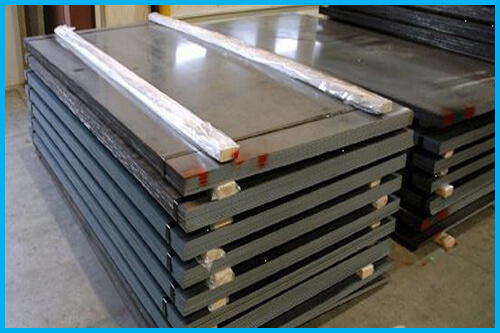

When it comes to industries like mining, construction, and manufacturing in India, wear-resistant steel plates are essential to protect machinery and extend equipment life. Wear plates are specially designed steel sheets that resist abrasion and impact, helping your operations stay efficient and reduce costly downtime.

In India, wear plates such as AR 400 are widely used due to their excellent balance of hardness and toughness. AR 400 offers a nominal hardness of 400 HBW (Brinell Hardness), making it suitable for harsh working conditions. These plates comply with international standards including ASTM A514, EN 10051, and DIN EN 10163, ensuring consistent quality and performance across batches.

Finding the right supplier is important. Trusted Wear Plates Manufacturers in India produce plates that meet strict chemical and mechanical specifications. Additionally, Wear Plates Distributors provide a variety of sizes and thicknesses, along with services like cutting and timely delivery to meet your specific needs.

The Indian market has grown significantly, and with increasing infrastructure development, the demand for abrasion-resistant wear plates continues to rise. Whether you require plates for earthmoving equipment, crushers, or liners, sourcing from reliable manufacturers and distributors guarantees the best value for your investment.

In summary, wear plates in India offer durability, high resistance to wear, and compliance with global standards. By choosing certified plates and reputable suppliers, you ensure your machinery stays protected and productive, even in the toughest environments.

Comments on “Wear Plates in India: Durable Solutions for Heavy-Duty Applications”